A well-known manufacturer in the

Chinese dryer industry

SERVICE

Search

Our patience to communicate with the user to

understand the user's actual needs, to provide

users with the best design

Copyright©2018 Jiangsu Xianfeng Drying Engineering Co.,Ltd.. ICP: 苏ICP备05005924号 Powered by www.300.cn Changzhou

Best Design

A well-known manufacturer in the Chinese dryer industry

PRODUCTS CENTER

XSG Series Rotary Flash Dryer

XSG Series Rotary Flash Dryer

Overview:

Rotary flash dryer is a new type of efficient fluidized drying equipment developed by our company to overcome the inefficiency and high consumption of static drying. In the design process, the dryer fully integrates the features of common dry-flow dryings such as air-flow drying, adopting their good points and avoiding their shortcomings, and enabling the whole dryer to have a reasonable process structure and superior performance with low consumption and high efficiency of fluidized drying.

Applications:

The dryer has a wide scope of applications and can be used to dehumidify and dry materials including fire retardants, molecular sieves, rubber additives, pesticides, pigments, dyes, fine chemicals, feeds, medicines, and some intermediates.

Principle:

The hot air enters the stirring and drying chamber from the bottom of the dryer through the air inlet at a suitable spouting velocity, which produces a strong shearing, blowing and rotating effect on the material. The material is micronized by centrifugation, shearing, collision and friction, enhancing the mass transfer and heat transfer. At the bottom of the dryer, the larger and wetter pellets are broken mechanically by the stirrer, and the granules with lower moisture content and smaller size are entrained by the swirling airflow and further dried during the rising. Gas and solid phases rotate. The inertia of solid phase is greater than the gas phase, the speed of two phases is larger, and the heat transfer between the two phases is strengthened, so the drying strength of the dryer is higher.

Features:

·There are many kinds of feeding device for choosing, and feeding is continuous and steady, it won't have aggregation.

·The material will not go bad in high temperature at the bottom of dryer where there is cooling device.

·There are air seal and shaft cooling device, to increase working life of transmission part.

·There is special device for air distribution, it will get balance inside.

·There are rotational flow plate and grading round inside the drying chamber. controling the moisture and size of material available.

·Because wind circle speed inside the drying chamber is high, and the staying time of material is short, can avoid material sticky on the inner surface and heat sensitivity material going bad.

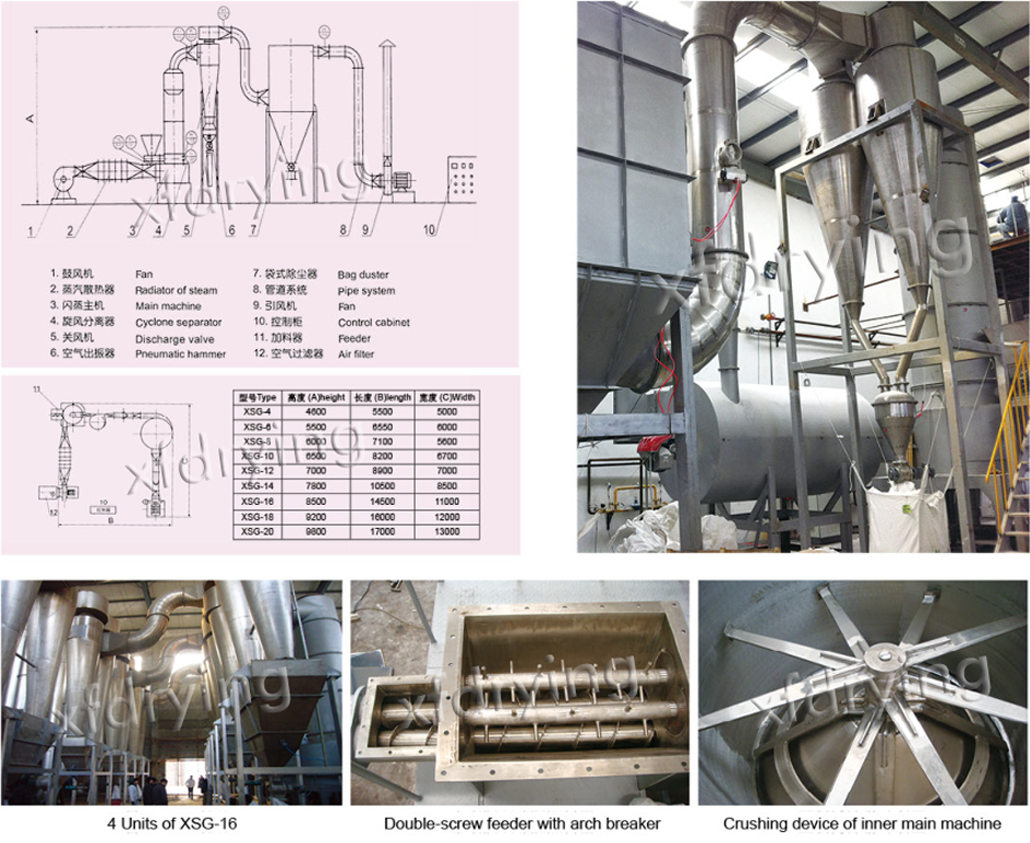

Sketch of Collocation:

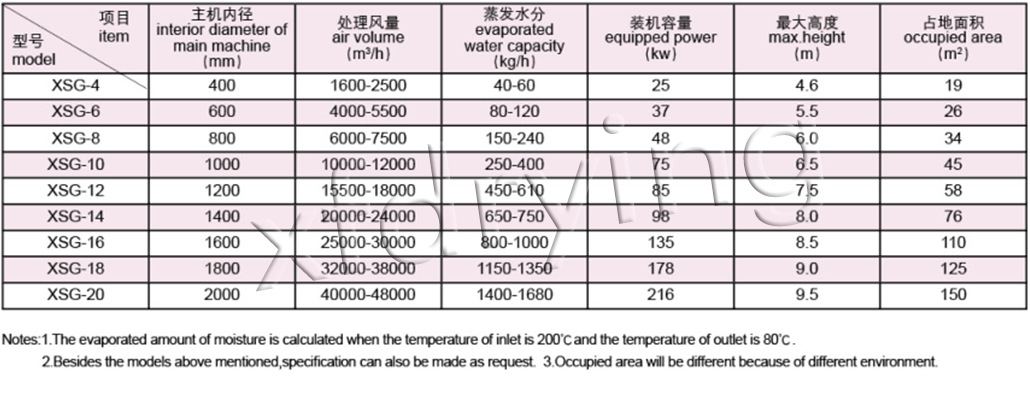

Technical parameters: