A well-known manufacturer in the

Chinese dryer industry

SERVICE

Search

Our patience to communicate with the user to

understand the user's actual needs, to provide

users with the best design

Copyright©2018 Jiangsu Xianfeng Drying Engineering Co.,Ltd.. ICP: 苏ICP备05005924号 Powered by www.300.cn Changzhou

Best Design

A well-known manufacturer in the Chinese dryer industry

PRODUCTS CENTER

GFG Series Efficient Boiling Dryer

GFG Series Efficient Boiling Dryer

Scope of application:

·Spiral squeezing granules, rocking granules, wet granulation at high speeds.

·Drying of wet granules and powdery materials in pharmaceutical, food, feed and chemical industry.

·Large granules, small pieces, and viscous bulks of granular material.

·Konjac, ammonium polypropylene sulfide and other materials whose volume may change in drying.

Working principle:

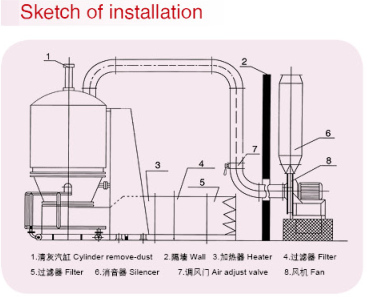

After heating and purifying, the air is introduced by the draft fan from the lower part and passes through the hole net plate of the hopper. In the working chamber, the fluidization is formed by stirring and negative pressure. After the moisture evaporates rapidly, the material is quickly dried as the waste gas is carried away.

Features:·The structure of fluidization bed is round so as ato avoid dead angele; ·Inside the trolley there is a stirrer in order to avoid agglomeration of raw material and forming channel of flow; ·The granule is discharged through the method of turning over.In this way it is very convenient.The auto discharging system can be designed if required; ·It is operated at the conditions of negative pressure and in seal.The air is filtered.Therefore it is simple in operation and convenient for clean.It is an ideal equipment that is in conformity with the requirements of GMP; ·The drying speed is fast and the temperature is uniform.In general,the drying time is 15-45 minutes each batch. |

|

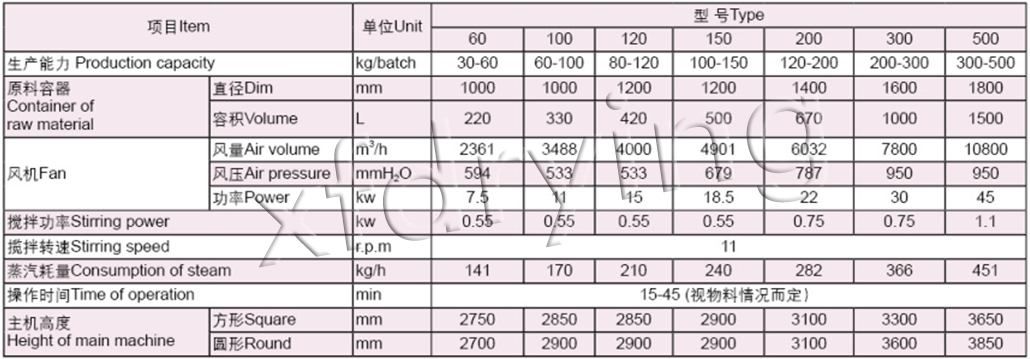

Technical parameters: